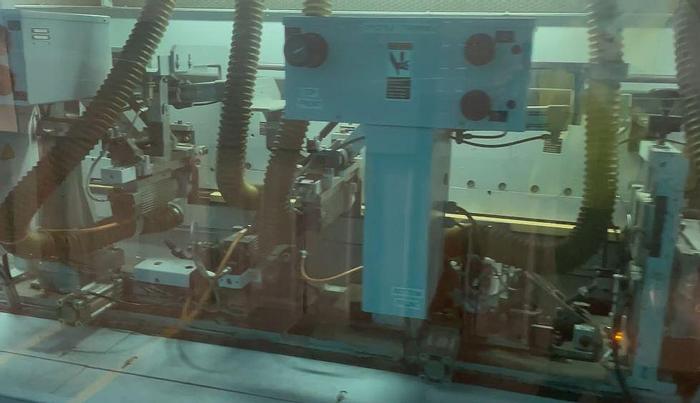

Homag KAL 210/7/A20/S2, 2007, W/ Return Conveyor, 3MM, 20MM strips, Pre-Mill, Scrape, Buff, Rieppe

Homag KAL 210/7/A20/S2, 2007, W/ Return Conveyor, 3MM, 20MM strips, Pre-Mill, Scrape, Buff, Rieppe

$24,950 (USD)

Available quantity:1

Description

As taken from service

Mfg. 2007

480V, 3Ph

Used Doucet return conveyor included with the edgebander

Mfr. specifications believed to be correct, but may need further verification.

Edgebander with Pre-Milling & Corner Rounding (4) Motor:

Working Capacity:

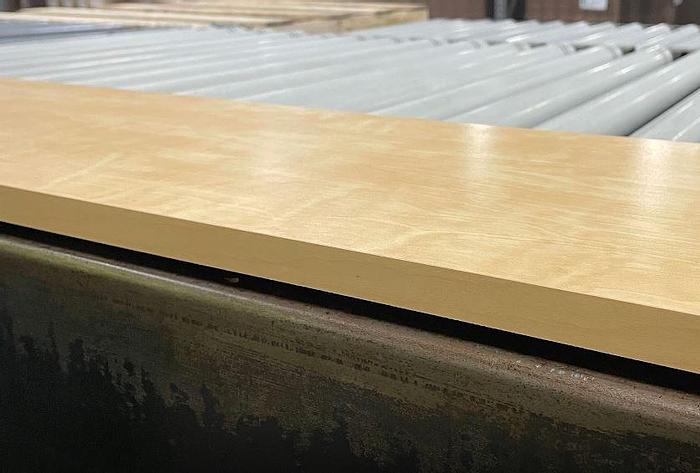

Edge thickness, coiled stock min/max, 0.3 – 3 mm (0.012. – 0.112″), straight edges, min/max. 0.4 – 20 mm (0.016 – 0.788″), panel thickness min/max. 12 – 60 mm

(0.472 – 2.362″).

Equipped with:

• Pre-Milling Station: Two vertical jointing spindles, KW 3.0 x 2 (HP 4.0 x 2) – 150 Hz, 9,000 RPM Motors; equipped with panel blow off device and SIKO digital counters for adjustments.

• Panel Pre-Heat Unit: Quartz lamp for heating substrate edge before glue application.

• Edge Magazine Combination: Strip processing and (2) – coil vertical magazine for quick coil changeover.

• Gluing System A 20: EVA (Hot Melt), Quick Melt hopper feeder & roller applicator (reversible).

• Pressure Section “C”: Servo controlled with (1) Large 150 mm dia. driven & (6) idle rollers; automatic servo adjusting pressure zone through program for varying edge thicknesses.Workstations:

• End Trimming Unit HL 84: KW 0.8 x 2 (HP 1.0 x 2) – 200 Hz, 12,000 RPM Motor ea. to cut excess edge on the front & back of the panel; pneumatic adjusting from chamfer to straight snip.

• Rough/Pre-Trimming Unit: Top & bottom, KW 1.5 x 2 (HP 2.0 x 2) – 12,000 RPM ea. motor. Height adjustment with the top pressure-beam and swiveling range +/- 1°.

• Profile Trimming / Corner Rounding “FF 12” Unit: Equipped with (4) motors for fine or profile trimming upper and lower edge, as well as trimming around the front & rear edge. KW 0.4 x 4 (HP 0.54 x 4) motor ea.

• .2.2 Kw (3.0 HP) Grooving Unit, 90 deg. horizontal/vertical with jump control

• Profile Scraping Unit PN 10: Top & bottom for thick PVC/ABS, pneumatically activated

• Flat Glue Scraper Unit: Top & bottom to remove potential glue squeeze-out.

• Buffing Unit: Top & bottom edge polishing.Complete With:

• Power Control PC 22: Controller functions in Windows environment and features: Keypad w/LCD flat screen display, fault diagnostic, OS9 real-time operating system.

• Variable feed-speed from 18 – 25 MPM (59 – 82 FPM); 80 mm feed track pads, and V-groove belt on top pressure beam which is motorized; motorized raising & lowering of top pressure beam through program selection.

• Spraying Units: (1) for anti-sticking on in-feed side of the machine, (1) prior to Buffing Unit for edge polishing.

• Other Features: SIKO Digital adjustments; electronic DC brakes on all trim motors, sound cabins for all trim workstations, standard adjustable outboard panel support.

Up to 6 Rieppe application control units to apply release ,anti-stick, anti-static and cleaning agents

Specifications

| Manufacturer | Homag |

| Model | KAL 210/7/A20/S2, 2007, W/ Return Conveyor, 3MM, 20MM strips, Pre-Mill, Scrape, Buff, Rieppe |

| Condition | Used |

| Serial Number | 006-85-200 |

| Stock Number | I-1-264 |